This weaving taught me two new things. One is that I further explored color, using a different variation than I have yet; with two colors in the warp, and four in the weft. The color affect of the check is still lively and interesting, but without warping with the two lightest shades (beige and natural) the result gave a more muted and softened color variation, less dramatic with no light blocks. I would like to explore this idea even more!

I think the most challenging thing about this piece, and anything I’ve woven to date, is that I did a double heddle threading with two different size reeds. It was definitely another long and arduous threading process, and after discovering I miscalculated the spacing the first time, I resolved there really was no way of going around it, that it had to be done right, and be done over. Of course, in doing it over I discovered a formula for myself, where I was only guessing at first, and so I have written my formula in my weaving notes.

This is going to be the last of the double reed threading for a while, for not only is it a very intensive warping process, but also if a mistake is made in the warp (as there was one, if you’ll notice the long run throughout the whole weaving) it is just not something I know how to fix and it tests my patience. Such was the case again, some threads misaligned and right off the start, the flaw was blaringly obvious, but this was merely a sample to test the process. The reed sizes I wanted to thread together in this project were 15 dent and 12.5 dent (per inch), but easier calculated in the metric sizes 60/10(cm) and 50/10(cm) , to get a sett of 25 epi. Its all there in the weaving notes, with technical threading photo gallery.

♣ Weaving Notes ♣

- Yarn: 20/2 mercerized perle cotton, 8400yds / 1 lb, Maurice Brassard, in colors; Rose Paudreux (P145), Natural (P100), Light Beige (P-2), and Flax (P-5109).

- Loom: Ashford Knitters Loom 20″.

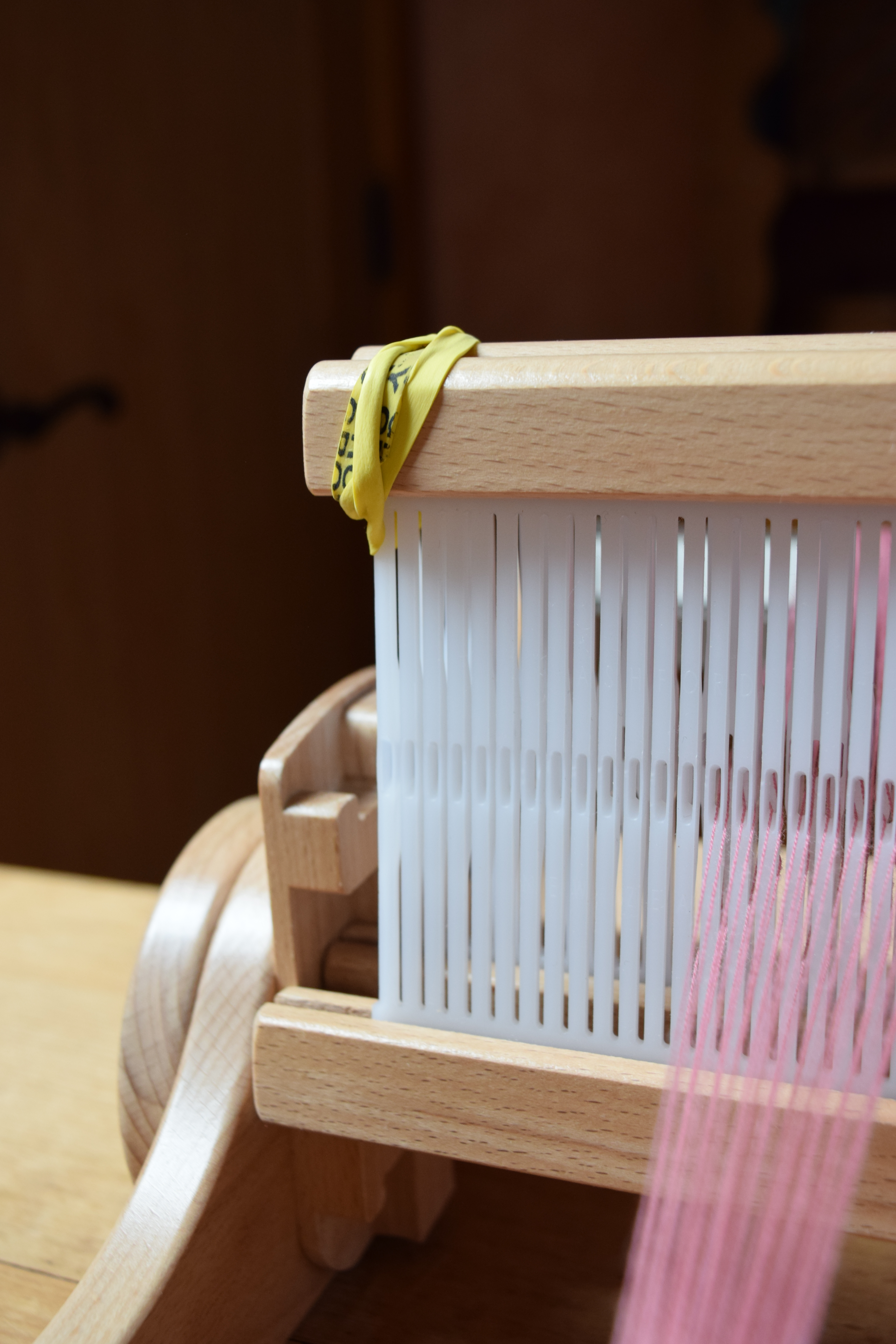

- Warp: Double threaded 4 ends per dent on first reed, then through a second reed using this method Using a heddle stand is rather necessary, Jeff made the one I use in tech photos below. I don’t know how to suggest an alternative, but if one has a couple of heavy objects or uses a bit of cleverness, one could rig a reed stand. Now, with the second reed forward, threading it through in a very seemingly complex manner, but it really isn’t. Warp length is approx 110 inches from apron rod to warping peg. See formula below.

- Number of warp ends: 432.

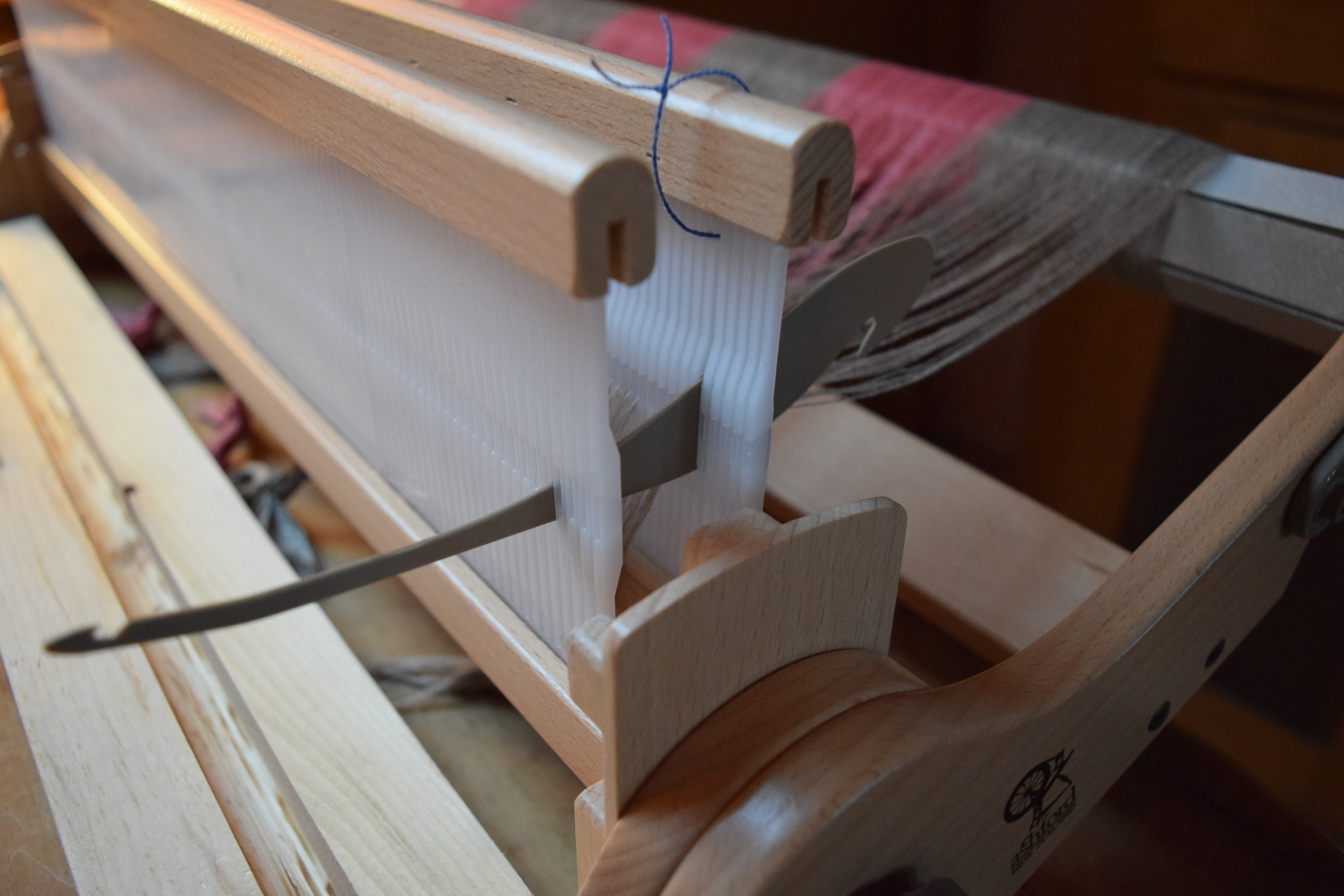

- Reed: Two rigid heddle reeds, one 15 dent and one 12.5 dent. I threaded through the 15 dent reed first, skipping 1 slot after every 4 slots threaded, and the second reed I threaded every slot. End result is as two 12.5 dent reeds, with 25 epi. See formula below. Note: After both reeds were threaded, I held them together with thick rubberbands as shown in photos.

- Sett on loom: Warp = 25 epi (ends/threads per inch), weft = 25 ppi.

- Sett after finishing: Warp 28 epi, and weft 28 ppi.

- Selvedges: I did not do floating selvedges, nor did I bother to double up and reinforce the selvedges, mostly because there was so much going on with threading through TWO reeds. I did use a temple.

- Color Pattern:

- Warp = [18 slots with 4 ends each slot (72 ends) flax, 18 slots with 4 ends each slot (72 ends) rose] REPEAT for a total of 3 pattern reps, and 432 ends.

- Weft = wound on to a 30″ stick shuttle; [30 wraps of flax, 50 wraps of light beige, 30 wraps of rose, 50 wraps of natural] repeat the sequence to end of warp.

- Finished: 1/4 inch turned hem, then washed and dried in machine, then pressed, measuring 80″ long and 15.5″ wide, and weighs 105g.

- Yardage: Total yardage used for finished piece = 1943y, figured from weight of finished piece and not including loom waste.

My formula for threading two graduating sized heddles together: All of the reed sizes for the Ashford rigid heddle looms, which many rigid heddle weavers have a size graduation of reeds:

2.5 dpi (10/10cm)

5 dpi (20/10cm)

7.5 dpi (30/10cm)

10 dpi (40/10cm)

12.5 dpi (50/10cm)

15 dpi (60/10cm)

I have most of the reed sizes for my Knitters Loom, but for the sake of very fine cloth weaving with my rigid heddle looms, I am writing down my formula for threading two reeds of graduating larger sizes together so that I can achieve epi’s greater than the finest single reed available for this loom, which is a 15 dent (60/10). I’ll add that It is far easier to use a single reed than to thread two together, so in the case of coupling the lower-dent reeds — I recommend just buying the single 15 dent reed, instead of double threading 40/10 with 30/10 (or two 30/10) reeds to get 15 epi, but for the sake of example I listed all the rigid heddle reed pairings in sequence, in the situation that it applies.

The reed that has fewer dents should be in front of the other, facing forward toward the weaving, where every slot and hole is threaded. The reed with more dents should be behind it, and when threading, skip 1 slot/hole as needed to align to the front reed. Off of the warp beam there will be spaces in the threading, but the reed facing the weaving is even with no empty slots/holes. Here are my calculations for a balanced threading across the warp . . .

- 60/10 & 50/10, thread as two 50/10 (thread 5, skip1) same as two 12.5/in= 25epi

- 50/10 & 40/10, thread as two 40/10 (thread 4, skip1), same as two 10/in = 20epi

- 40/10 & 30/10, thread as two 30/10 (thread 3, skip1), same as two 7.5/in = 15epi

- 30/10 & 20/10, thread as two 20/10 (thread 2, skip1), same as two 5/in = 10epi

- 20/10 and 10/10, thread as two 10/10 (thread 1, skip1), same as two 2.5/in = 5epi

Click 1st photo to go to slideshow…

It looks like work that takes a lot of patience and focus, but the end product is gorgeous. This one has such a silky sheen to it. I just love that mix of colors. Once you get into the process of warping, is it difficult to pick up where you left off if you take a break?

Very easy to pick up at any time, because I’ve got each color wound with counted number of wraps on the stick shuttle, so I just weave it until the color runs out, and go on to the next; 30 wraps for the pink and the flax color, and 50 wraps for the natural and the light beige. Next time I’ll try it a little differently.

I love the sheen too, its because its mercerized cotton, and comes off almost like silk. The pieces I wove at first with unmercerized don’t have that sheen like Scarf No. 1

This is the finest cotton I can find, at 8400 yards per pound, and so almost like sewing thread. Next I am going to weave the same cotton in a single finest (15 dent) reed, it will be super open and gauzy. We’ll see how it goes… going to warp for it this morning !

I folded up the big table loom (and it is really big!) and put it away at the beginning of the month and its tucked away with the 48″ RHL out of sight in one of the loft closets, the one where Abelene lives, and they’re all in there having a party while I just overwork the little 20″ Knitters Loom testing all these ideas. 🙂

Thanks for your support and encouragement! xx

ooooh that next experiment sounds awesome. Can’t wait to see that. Now I’m picturing Abelene doing the Hustle with a loom. Hehehe

A girl has gotta do what she’s gotta do! 🙂

I meant to add to my last reply; the same fine thread weight in mercerized cotton is about $7.50 per 100g ($11.50 per 150g cone), and silk is about $26 per 100g ($70 per 250g cone) so I’m loving the very silky mercerized cotton!

Tidy little savings!

Very! And no moth babies have to die either. 🙂

That fabric is stunning!!

Do you think you might get a little Ashford Knitters’ Loom too? I need to share my weaving notes with someone. 🙂